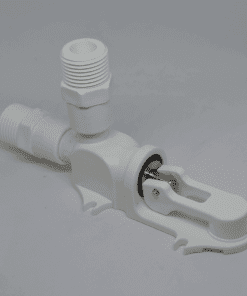

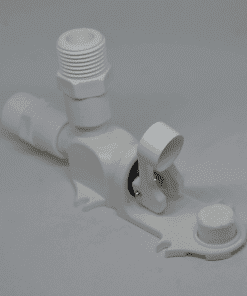

RO Automatic Shut Off Valve

$19.00 Including GST

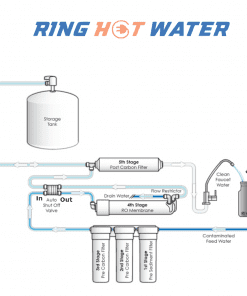

RO automatic shut off valve for Reverse Osmosis systems that have a storage tank or float shut off.

In stock

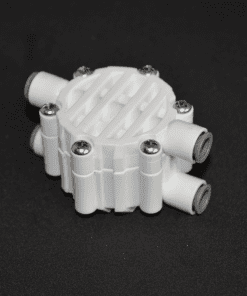

RO Automatic Shut Off Valve

Automatic shut off valve for Reverse Osmosis systems that have a storage tank or float shut off. Shuts off when the tank reaches approximately 60 of the inlet water pressure. Built in 1/4″ quick connect tube fittings for easy installation.

Benefits of Auto Shut Off Valve for Home RO Systems

● Automatic operation of the RO System

● Saves water by shutting off the feed water once the tank is full

● Easy to install

● Completely mechanical operation; no electricity is required

● Suitable for most residential RO systems up to 100 GPD

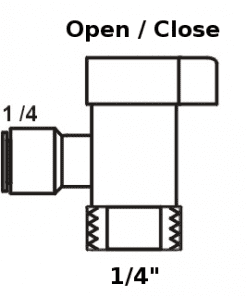

● Push in fitttings that connects to 1/4″ tubing.

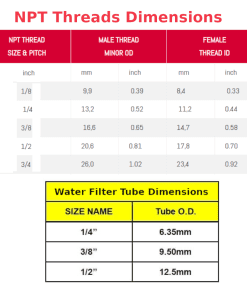

Reverse Osmosis Shut Off Valve Specifications

● Quick fit push in fittings

● Polypropylene

● Maximum pressure 100 PSI

● Maximum temperature 45c

● Inlet Port 1/4″ Tube

Applications for automatic shut off valve

● Point of Use (POU) Drinking Water Systems

● Home RO Systems

● Office

● Institutions

● Lab

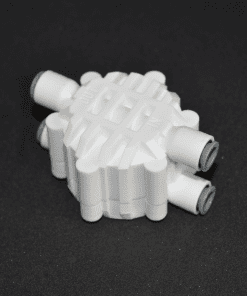

Automatic shut off valve is made by Tiger and is a manufacturer of high quality push-in fittings, pipe and plastic plumbing systems to a wide variety of industries, Tiger fittings are easy to use, simply push the tubing all the way in then pull on the tubing to lock for a high water pressure sealed connection

● No need for C clip to lock in tube

● Double O’rings, Double protection

● Push-fit technology

● Quick disconnection without the need for tools

● High chemical resistance

● Food Quality and suitable for potable liquids and pure water applications

●Not suitable for compressed air and vacuum applications

| Food Quality All these fittings are produced in Food and Drug Administration (FDA) compliant materials and are therefore recommended for food quality applications |

Double O’rings, Tiger Fittings Double Protection

How Tiger fittings work

To make a connection, the tube is simply pushed in by hand; the unique patented Tiger double O’ring locking system then holds the tube firmly in place without deforming it or restricting flow.

Materials of construction

Tiger fittings are made up of three components:

Bodies are produced in an acetal copolymer or polypropylene.

Double ‘O’ rings are Nitrile rubber or EPDM.

Collets are produced in acetal copolymer or polypropylene with stainless steel teeth.

To disconnect: push in collet and remove tube

Tiger fittings are suitable for the following pressures and temperatures.

| Temp. | Max Working Pressure 175 psi, 12 bar | |

|

Fluid 5 ~ 45c |

Ambient -20 ~ 65c |

|

| Max.Torque. | ||

Maximum Torque Values for Plastic Threads BSP, BSPT & NPT.

Plastic threads are not generally as strong as brass threads. Customers and end users should be aware of this when choosing products for their applications. Over-tightening of plastic threads will cause undue stress and eventual cracking and leakage. The maximum torque figures for BSP and BSPT threads used in Tiger fittings in mating threads conforming to the relevant BS or International thread standards.

| Weight | 0.100 kg |

|---|

Be the first to review “RO Automatic Shut Off Valve” Cancel reply

Related products

1/4" Water Filter Fittings

Reverse Osmosis Parts

1/2" Water Filter Fittings

Reverse Osmosis Parts

Reverse Osmosis Parts

Reverse Osmosis Parts

1/4" Water Filter Fittings

Reverse Osmosis Parts

Reviews

There are no reviews yet.