Reverse Osmosis Check Valve

$12.00 Including GST

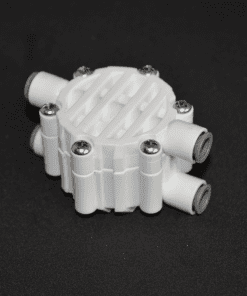

Easy to use reverse osmosis check valve simply push in fitting for a high water pressure sealed connection.

In stock

Reverse Osmosis Check Valve

Our high-quality push-in fittings, pipe, and plastic plumbing components are built specifically for reverse osmosis systems. This including Reverse Osmosis Check Valve and flow restrictor reverse osmosis setups. Using push-fit technology, you can install these components quickly and easily. Just push the tubing in and pull to lock it in place, creating a reliable, high-pressure seal. This design eliminates the need for tools, making it ideal for DIY or professional reverse osmosis installations.

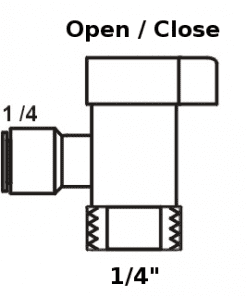

The elbow fitting (1/4″ tube x 1/8″ NPT male) provides high chemical resistance and allows for quick disconnection, which is essential in maintaining or upgrading reverse osmosis check valve assemblies. Additionally, it meets food-grade standards, making it suitable for pure water and potable water applications. However, these fittings are not intended for use with compressed air or vacuum systems. For dependable performance in any reverse osmosis system, including those with flow restrictors and check valves, these fittings deliver lasting value and simplicity.

Check Valve Reverse Osmosis

| Food Quality All these fittings are produced in Food and Drug Administration (FDA) compliant materials and are therefore recommended for food quality applications |

Materials of construction

Fittings for flow restrictor reverse osmosis systems consist of three parts: durable bodies made from acetal copolymer or polypropylene, double ‘O’ rings in Nitrile rubber or EPDM for a tight seal, and collects with stainless steel teeth to grip tubing securely.

To disconnect: push in collet and remove tube

Fittings are suitable for the following pressures and temperatures.

| Temp. | Max Working Pressure 175 psi, 12 bar | |

|

Fluid 5 ~ 45c |

Ambient -20 ~ 65c |

|

| Max.Torque. | ||

Maximum Torque Values for Plastic Threads BSP, BSPT & NPT.

Plastic threads, commonly found in reverse osmosis systems, including flow restrictor reverse osmosis and reverse osmosis check valve setups, are not generally as strong as brass threads. Customers and end users should consider this when selecting products for their applications. Over-tightening plastic threads can cause excessive stress, leading to cracking and leakage. The maximum torque figures for BSP and BSPT threads used in Tiger fittings—often used in reverse osmosis systems—comply with relevant BS and international thread standards.

| Weight | 0.01 kg |

|---|

Be the first to review “Reverse Osmosis Check Valve” Cancel reply

Related products

Reverse Osmosis Parts

Reverse Osmosis Parts

1/4" Water Filter Fittings

Reverse Osmosis Parts

Reverse Osmosis Parts

Reverse Osmosis Parts

1/4" Water Filter Fittings

Reverse Osmosis Parts

Reviews

There are no reviews yet.